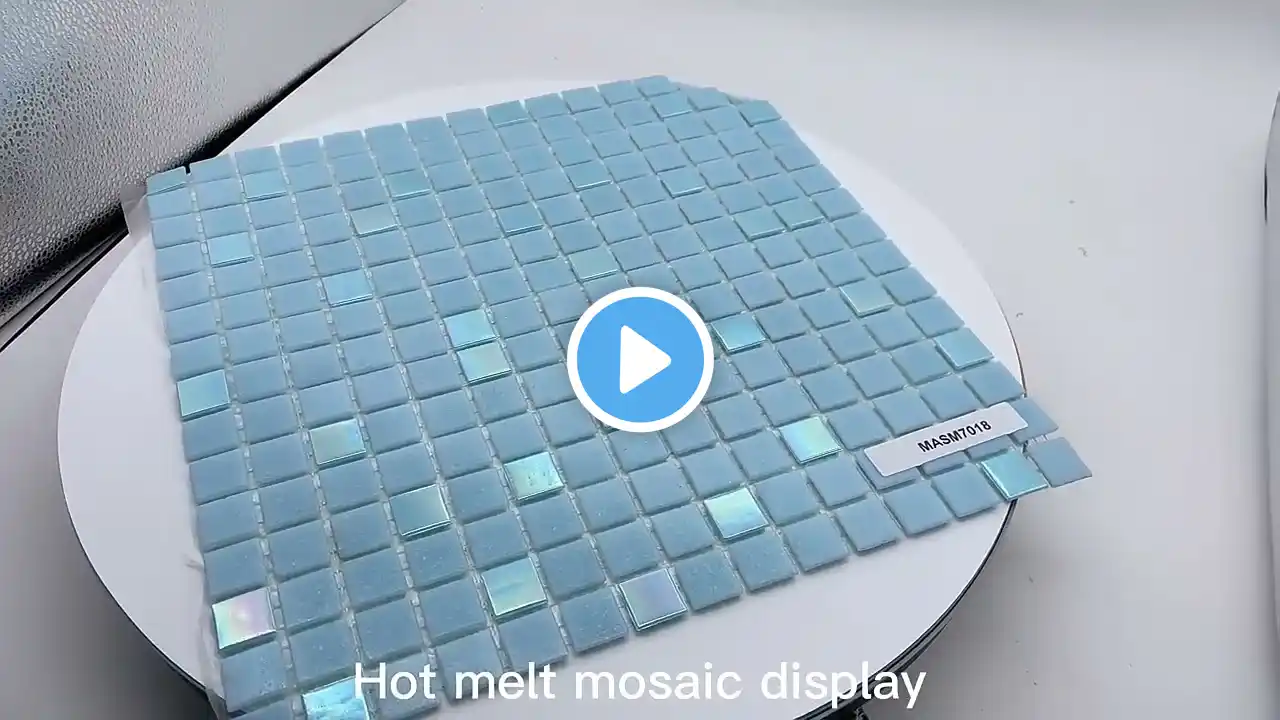

The Magic of Hot-Melt Glass Mosaics

Production Process Raw Material Preparation: Transparent flat glass of a specific thickness (usually 4-8mm) is cut into mosaic-shaped blocks. Color Application: Colored glazes are applied to one side of the glass, creating beautiful patterns. A layer of white glaze is added to enhance durability. Firing and Shaping: The glass blocks are placed on a high-temperature resistant ceramic pad and moved through a kiln. The glass is then fired at high temperatures, forming an arc edge. Cooling and Quality Control: After cooling, the mosaics are inspected for quality. Qualified pieces are then packaged with a back mesh design for easy installation. Applications Hot-melt glass mosaics are incredibly versatile and can be used in a variety of settings, including bathrooms, living rooms, swimming pools, hotels, and resorts. Their durability and beauty make them perfect for both indoor and outdoor installations. Why Choose Hot-Melt Glass Mosaics? Durability: High-temperature firing ensures long-lasting quality. Aesthetic Appeal: Vibrant colors and smooth edges create a luxurious look. Easy Installation: Back mesh design simplifies the installation process. Step into the future of decorative glass with hot-melt glass mosaics and transform any space into a work of art.#mosaicfactory #interiordesign #mosaic #homedecor #mosaictiles #tiles #mosaictile #tiledesign #mosaicfactorytiles #stone #factory #marble #tile